Mud and Rammed Earth Structures

At the firm recently we have been discussing the embodied energy of the materials we use to build (see our post two weeks ago, on the Greenhouse Gas Emissions of various types of insulation). Because, while the operation of the building (heating, lighting, cooling, and other plug loads) constitutes the lion’s share of emission over the lifetime of the building, when we build a passive house or net-zero building these emissions are mitigated almost or totally completely… leaving the embodied energy of the materials as the main Greenhouse Gas emissions generator. Therefore with energy efficient buildings it is important to consider the energy required to manufacture and transport the parts required to build it. Within this vein we will be publishing a series of blog posts exploring different “natural” building materials and some examples of their use.

Natural Architecture, in the sense we are using it, is defined as a method of building which uses materials which are minimally processed with little to no manufacturing or industrial requirements and is produced/grown/harvested locally. Some groups use “natural” or “organic” architecture interchangeably, and invest both terms with complex ethical and aesthetic values, resulting in bio-mimetic shapes or neo-archaic final results… in our perspective this is not necessary. Using natural materials doesn’t mean you need to adopt a different political or ethical viewpoint, it simply means that instead of using Concrete Masonry Units for wall construction you might use rammed earth or adobe. Indeed, the more one looks into the possibilities for natural architecture, the more quickly it becomes apparent that un-manufactured and minimally processed materials can be used in myriad ways: as walls, floors, and even roofs! This blog post surveys a few methods for building with earth (also called cob or adobe).

Rammed earth homes and buildings are found around the world: a result of the ubiquity, durability, and functionality of the materials from which they can be assembled.

“More than 30 percent of the world’s population continues to use earth as a building material” (source)

They can be made with dirt, chalk lime, gravel, clay, sand, and can include cement, straw, and even animal blood. They can be among the most sustainable materials to build with, especially when made with soil from the site, and when lime or other natural stabilizers are used in place of concrete. Because dirt is inert, and does not contain preservatives, harmful chemicals, or VOC’s (volatile organic compounds) indoor air quality can be very clean. Earth walls are also fire resistant, can store thermal energy (store heat during the day and release it at night), can control humidity, are durable, can be easily repaired, and can have a beautiful finish.

Below is a mosque in Mali made from sun-dried earth blocks covered in plaster that has, with repairs, lasted hundreds of years.

There are two general methods of working with earth: one involves loose material, the other cast or compressed material:

1.) In the first method a formwork is made and the material is poured into the framework and tamped down in layers. This is known as “Rammed Earth”. The “earth” in this case is sand mixed with gravel and clay. The mix can also include a stabilizer such as lime or cement to add additional strength, although this is unnecessary and can compromise the sustainability of the wall. Once the wall is complete the formwork can be removed right away, exposing the finished wall. Pigments and dies can be included in each layer to create beautiful colour effects as illustrated in the Nk’Mip Desert Cultural Centre in Osoyoos, British Columbia, Canada.

“Rammed earth is probably the single lowest environmental impact building system that is readily and commercially available today for solid masonry buildings” (via wikipedia)

There are variations on this method, such as cob which does not use the tamping or the formwork, but involves the application of the material in rows which are then smoothed into a unified surface. Another variation is pouring wet adobe (made from earth and often organic material) into a formwork of reinforced metal which is then let to set.

One team of Canadians, Cobworks, on the West Coast has begun a resurgence of cob-building, with over 10 completed homes to date http://www.cobworks.com/

One unique aspect of this method is that when the formwork is removed the surface can be carved or etched with patterns. This allows hand-sculpted decorative or functional ornament on the interior or exterior . See the shelves on the photo above from Cobworks Deacon Vale Farm project.

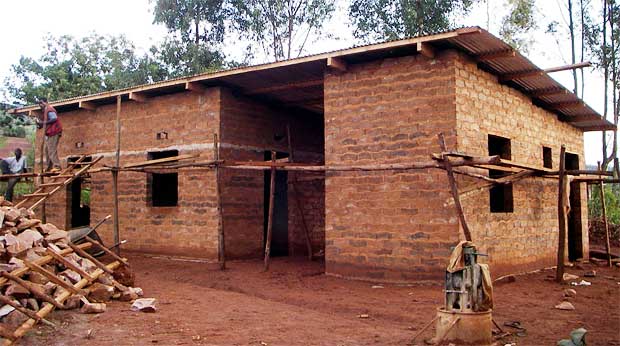

2.)The other type of method for building with earth is when the material is compressed, or cast and left to dry into bricks, such as adobe or “Earth Block” construction. In the case of compressed earth blocks, either an on-site compressor-machine or remote factory compacts the earth to 50% of it’s original volume. A stabilizer can be used, such as lime or cement to bond the materials together. The result is a “brick” that can be laid with a muddy slurry acting as the mortar.

In the case of traditional adobe-use, the blocks are cast in molds and left to dry before being assembled like bricks, and then encased within a layer of dirt-plaster. In boths cases the earth blocks and adobe are assembled much like brick, and can include a surface treatment with plaster, water resistant coatings, rain-screens or siding.

The suitability of rammed earth for cold climates has been demonstrated for large parts of Canada’s praries, where it is combined with exterior insulation. As the push for sustainable, net-zero building gather strength we can expect to see Building Code departments and architects increasingly turn to rammed earth as a sustainable alternative to concrete walls and floors.

There are so many exciting design potentials with rammed earth: we look forward to seeing how the research develops as well as the opportunity to begin introducing rammed earth elements within our projects.