Window Thermal Performance: Comparing High Performance Wood-Aluminum windows with Fibgrelass windows

Windows are the weakest elements of a building in terms of thermal performance due to their low thermal resistance in comparison to other more-highly insulated elements of a building enclosure (wall, roof, floor). Therefore selecting the right windows is an essential aspect of any high performance or Passive House window.

As an architecture firm offering clients high performance and Passive House Buildings, Cooelarth believes having an in-depth knowledge of windows is very important. We have done a lot of research into window suppliers: comparing price, performance, and quality, and have found there can be massive spread in the cost and performance of windows.

This blog post grew from a discussion we were having in the office a few weeks ago about the size of the frames in wood-aluminum “passive house” windows compared to fibreglass windows — the frames are almost twice as thick (this also applies to PVC windows, whose frames can be just as larger, or larger, then wood-aluminum windows). The content of the discussion was largely based around the following three points:

1.) The thermal performance of wood-aluminum windows is generally much higher than fibreglass… but at a significantly greater cost.

2.) With wood-aluminum window frame’s being thicker then fibreglass this means you need to order larger windows in order to keep the glazing area the same… and therefore you will have less highly insulated wall area.

3.) Taking the two points above this means with wood-aluminum windows you end up substituting cheap highly insulated wall insulation with costlier poorly insulated window frames in order to acheive the same glazing area as fibreglass.

After the discussion we decided to pursue this line of inquiry further to understand the implications, which seemed interesting and novel.

To guide this analysis, we formulated the following hypothesis:

When comparing wood-aluminum windows with fibreglass windows, if we keep the glazing area the same size for both, the decreased thickness of the fibreglass window frame will result in more area of wall insulation, which will improve the effective thermal resistance of the fibreglass window when compared to the wood-aluminum window.

Before we launch into heart of our analysis, we’d like to explain the three main elements which compose a window:

1.) Glass. In the ‘industry’ glass is called “glazing” and even more accurately in the case of a double or triple-pane window, “Insulted Glazing Unit (IGU)”. An IGU is composed of multiple panes of glass with inert gas between the layers for added thermal resistance (typically argon). The glass panes are seperated by a Thermal Spacer which is what creates the space for the gas. The area of the window with the highest thermal performance is the “centre of glazing”, and more generally is the IGU itself.

2.) Frame and Rails. The frame and rails in windows can be made of wood, aluminum, a combination of wood and aluminum, fibreglass, and PVC, to name the most common. The frame supports the IGU and the mechanism, and include the gaskets for air-sealing and drainage channels for moving water away from the interior.

3.) Hardware. Including the opening mechanism, hinges, locks, screens, etc.

We strove to conduct a data-based analysis of the windows using available data to figure out their effective thermal resistance to test the above hypothesis.

Methodology of Analysis

The fibreglass and wood-aluminium windows were compared with the same glazing dimensions. The width of the frames, thermal resistance of the frame and glazing, and cost were based on real windows from suppliers we like and have used multiple times at Coolearth. We assumed the wall construction would be a typical stud wall with 6″ of external mineral wool insulation. For the fibreglass windows we assumed that the difference in the area of the fibreglass frames versus the wood-aluminum frame would be insulated wall.

The following thermal resistance (R-value’s) were used for the starting point of our analysis:

| Fixed wood-aluminum window | R-7.81 |

| Operable wood-aluminum window | R-7.58 |

| Fixed fibreglass window | R-6.39 |

| Operable fibreglass window | R-6.17 |

| Wall insulation | R-25.2 (6″ external mineral wool insulation) |

Similarly, the total cost of each assembly was calculated using the following rates:

| Wood-Aluminum window | $121.80/ft2 |

| Fibreglass window | $82.00/ft2 |

| Insulation | $6.42/ft2 |

The total cost of each assembly is as follows:

| WINDOW TYPE | COST | % COST DIFFERENCE TO WOOD-ALUMINUM |

|---|---|---|

| Fixed Fibreglass | $1,656.13 | -41% |

| Operable Fibreglass | $1,763.45 | -43% |

| Fixed Wood-Aluminum | $2,742.02 | – |

| Operable Wood-Aluminum | $3,142.54 | – |

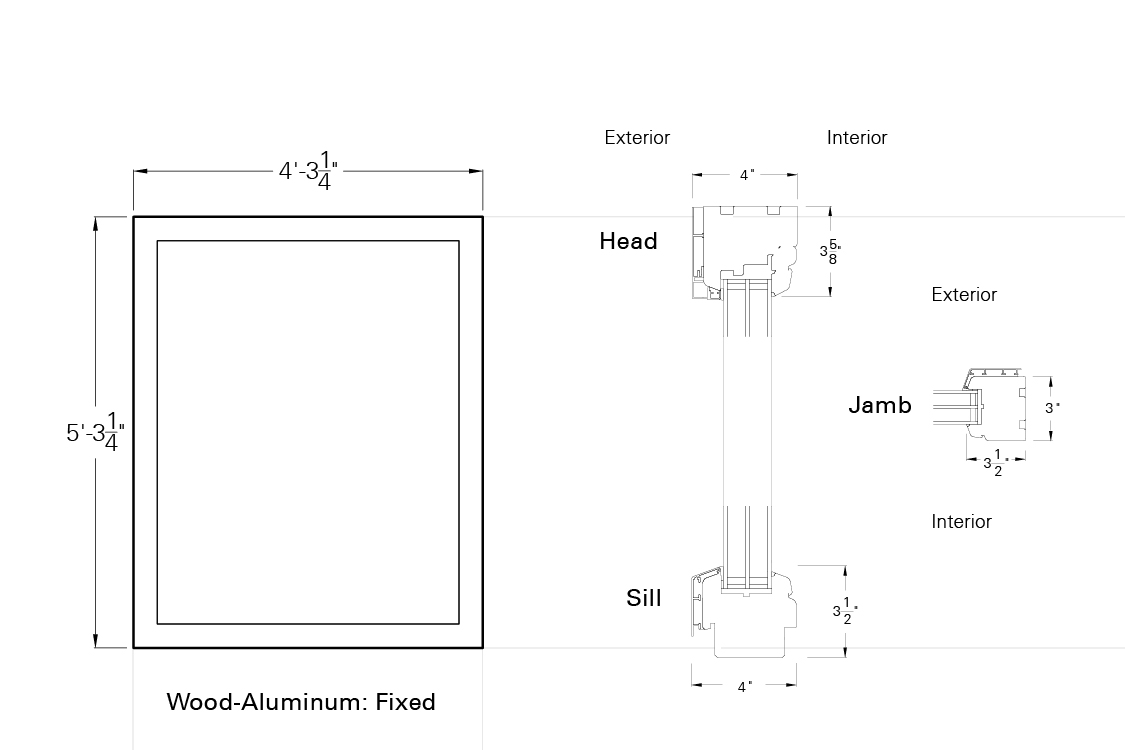

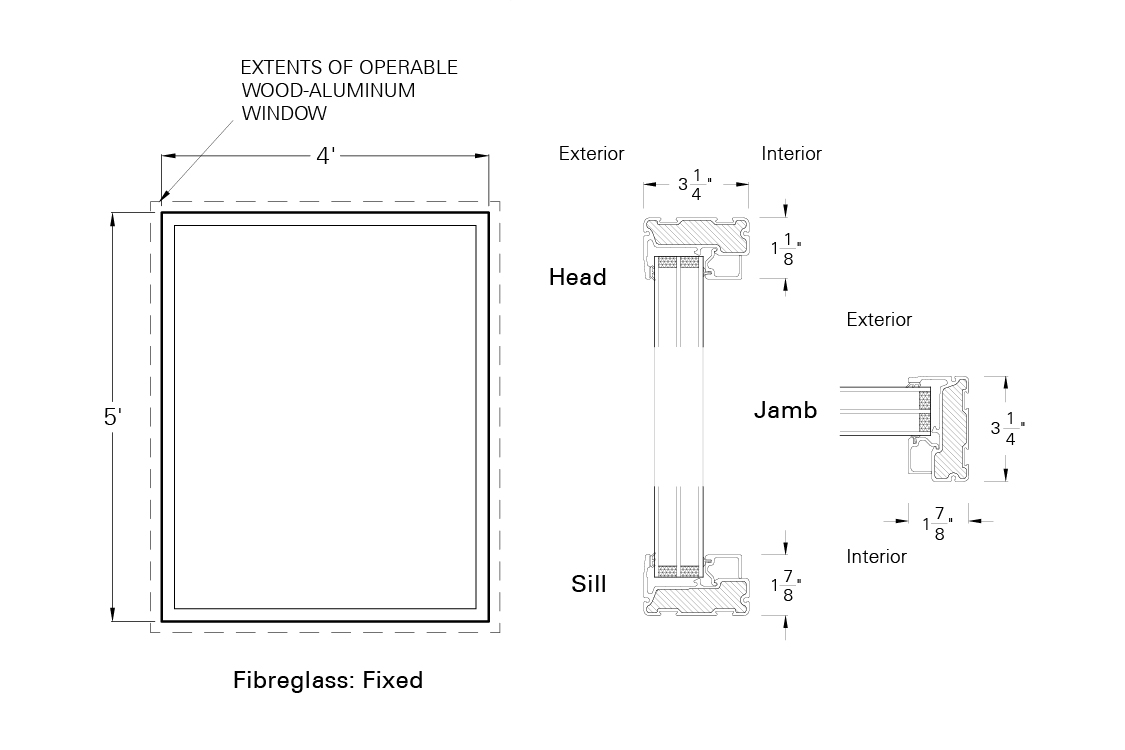

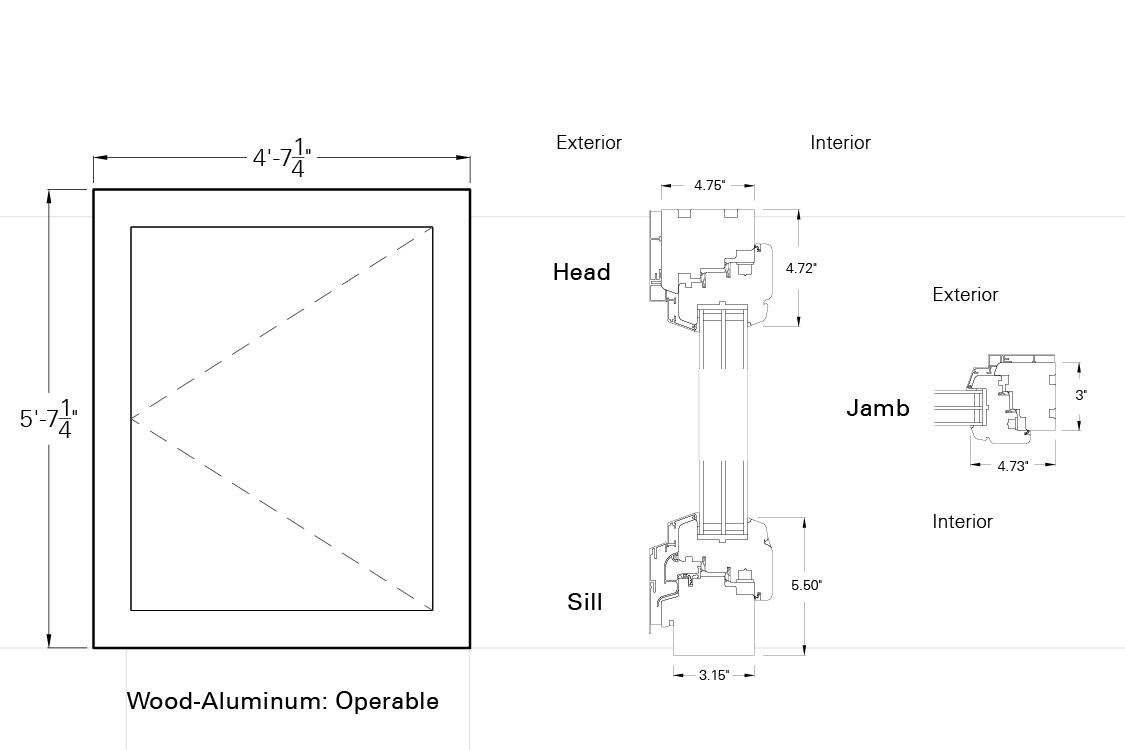

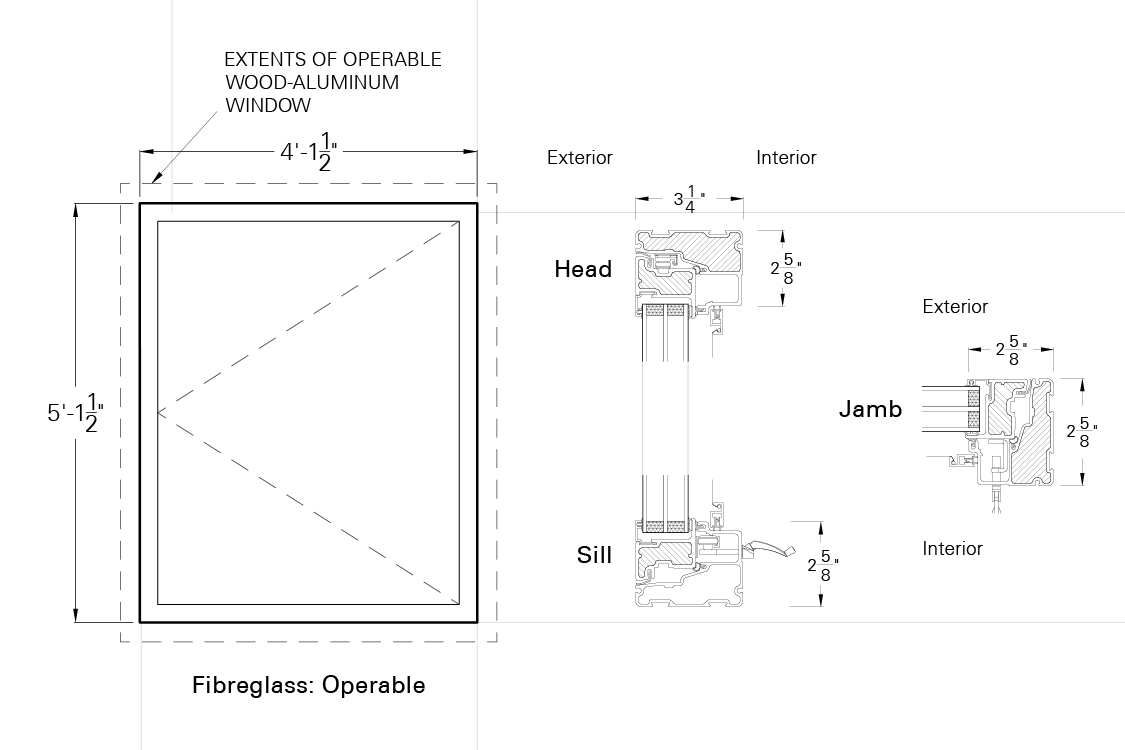

The following dimensions and profiles were used for each window:

Fixed Windows

Operable Windows

Results and Analysis

Based on our analysis the smaller frames of the fibreglass window, when compared to the thick frames of the wood-aluminum window, allows for additional wall insulation which improves the effective performance of the window beyond the initial stated R-value.

| WINDOW TYPE | INITIAL WINDOW R-VALUE | % PERFORMANCE DIFFERENCE TO WOOD-ALUMINUM | EFFECTIVE WINDOW R-VALUE | EFFECTIVE % PERFORMANCE DIFFERENCE TO WOOD-ALUMINUM |

|---|---|---|---|---|

| Fixed Fibreglass | R-6.39 | -18% | R-6.97 | -12% |

| Operable Fibreglass | R-6.17 | -23% | R-7.14 | -6% |

| Fixed Wood-Aluminum | R-7.81 | – | R-7.81 | – |

| Operable Wood-Aluminum | R-7.58 | – | R-7.58 | – |

For instance at face value, the fixed fibreglass window performs 18% worse then the fixed wood-aluminum window. However by including the area of the wall that the wood-aluminum window frame would occupy as part of the R-value of the fibreglass window, this improves the effective thermal performance of the fixed-fibreglass window by 6%, resulting in the fixed-fibreglass window performing only 12% worse then the wood-aluminum instead of 18%.

A bigger increase in performance is seen when looking at the operable windows — due to the larger size of the wood-aluminum window frames when compared to those of the operable fibreglass frames. In this case, a 17% performance improvement is seen when the operable windows are considered.

Conclusion

For both fixed and operable windows, the wood-aluminum window gas a greater R-value than a fibreglass window “on-paper”. However, when the additional wall insulation permitted by the smaller fibreglass frame is taken into account, this performance difference decreases. Considering that the fibreglass window costs 40% less this is an interesting result.

In projects with strong budget constraints the fibreglass windows are worth considering.

Next Steps

One interesting result of this analysis is the realization that if fibreglass window suppliers could increase the thermal resistance of their IGU’s, they could outperform wood-aluminum windows, likely at a significant cost advantage.

For instance, the IGU of the fibreglass window used in the above analysis has a thermal resistance of R-7.1, whereas the IGU of the wood-aluminum window has R-8.7. If the fibreglass window was to have the same IGU as the wood-aluminum window, the results of our analysis would be as follows:

| WINDOW TYPE | INITIAL WINDOW R-VALUE | % PERFORMANCE DIFFERENCE TO WOOD-ALUMINUM | EFFECTIVE WINDOW R-VALUE | EFFECTIVE % PERFORMANCE DIFFERENCE TO WOOD-ALUMINUM |

|---|---|---|---|---|

| Fixed Fibreglass w/improved IGU | R-7.44 | -8% | R-8.08 | 0% |

| Operable Fibreglass w/improved IGU | R-7.08 | -10% | R-8.14 | +4% |

| Fixed Wood-Aluminum | R-8.12 | – | R-8.12 | – |

| Operable Wood-Aluminum | R-7.83 | – | R-7.83 | – |

These results suggest that fibreglass window frames with IGU’s equivalent to those available on Passive House wood-aluminum windows could match or even out-perform wood-aluminum windows at likely a substantial cost discount, when taking the wall area into account.

However, considering that the IGU for the fibreglass windows is 1-1/2″ whereas the wood-aluminum IGU is 1-7/8″ the fibreglass frame profile would need to be modified to fit the thicker IGU.

Further Research

We will be continuing our in-depth analysis of windows over the coming weeks, by doing a blog post looking at the benefits of over-insulating window frames to increase the effective R-value. Stay tuned!

Special Thanks to Cindy, Renée, and Andrea for their help in research for this post!